Major Drilling Indonesia hydrofracking team shown at Freeport Indonesia’s Deep MLZ mine.

A recently published article in PT Freeport Indonesia’s e-BeritaKita monthly bulletin is a trove of insightful information about a specialized drilling process: hydrofracking—what it is, how it works, and how it’s done. PT Freeport and Major Drilling have sustained a long-time partnership in Indonesia, and teams there are currently supporting the blockcave and hydrofracking work to enhance the world’s largest gold mine in the Grasberg District. The article brings greater understanding about the challenges and solutions found at the Deep Mill Level Zone (DMLZ) underground mine that is part of the Grasberg District.

Major Drilling’s LM110 drill used in underground hydrofracking and blockcave work.

The article quotes Mark Johnson, President of Freeport-McMoRan Indonesia saying, “In block caving, we rely on the rock breaking along natural fractures once a certain span is achieved. When this natural breaking didn’t happen as expected in the DMLZ, we began seeing higher stresses in the supporting rock until It couldn’t take it anymore, resulting in a sudden release of stress or mine-induced seismicity.”

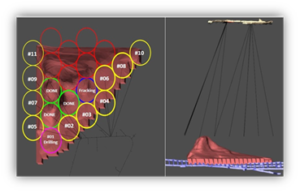

This figure shows the targeted areas Major Drilling typically uses to drill and break up cave geology using hydrofracking and blockcaving techniques.

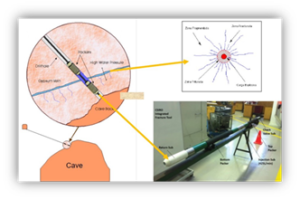

Existing tools required to safely achieve mine targets were not sufficient to mitigate the mine-induced seismic challenges, so the company decided to use hydrofracking to soften the rock mass, which has proven effective. Consequently, the first of three hydrofracking pumps were commissioned in early 2018.

Further details in the article explain how engineers at Freeport McMoRan teamed up with a trusted hydrofracking parts manufacturer to build the high-pressure pumping systems and support equipment based on the mine site requirements.

Operation details of the hydrofracking approach by Major Drilling teams in Indonesia.

PT Pontil (subsidiary of the Major Drilling Group) has been supplying drilling services to Freeport for more than 21 years, predominately through the GeoEngineering Division. PT Pontil recently began support of the underground mining operation according to Mark Wiki, Major Drilling’s PT Pontil Project Manager at the site.

“With the high seismic activity underground, we are working in partnership with Freeport to hydro-fracture the areas of concern, “ said Wiki. “This technique is new to site and it has been a team effort from both parties to successfully execute, with good results.”

The Major Drilling team is responsible for operating and maintaining the equipment associated with the specialized drilling process along with communicating to the Freeport engineers the progression of fracs as per Freeport’s instructions. These team efforts result in knowing ideal fracture sizing, finding how long fractures will take to form, discovering the necessary pressure to form a fracture, and determining water needs to produce a fracture.

Quoting Ian Edgar, PTFI Vice President of Underground Engineering, the monthly bulletin states, “The fracking equipment is very sophisticated, and the Pontil team operating it has become proficient with it very quickly. It achieved a larger fracture in less time than we had originally expected.”

Details of the hydrofrack control room at Freeport Indonesia’s Deep MLZ mine.

Major Drilling is proud of its long-term working relationship with PTFI. “Over the years we’ve been able to build a strong team allowing us to react quickly to Freeport’s needs both productively and safely,” said Kerryn Hornby Major Drilling’s Indonesia Branch Manager. Major Drilling currently operates several surface and underground drills in the Grasberg District. Among the underground drills, a good portion are dedicated to supporting the hydrofracking project. Hornby explained how this equipment represents how Major Drilling applies its exceptional resources in both equipment and personnel to make the DMLZ project an ongoing success.

Pictured from left to right are Kerryn Hornby, Major Drilling Indonesia Branch Manager; Kevin Slemko, Major Drilling Corporate Business Development Manager; and Mark Wiki, PT Pontil Project Manager for Major Drilling, on site at the DMLZ mine in Indonesia.

Producing excellent results like this for its partners is a core value at Major Drilling. Jon Emmerzael, Major Drilling’s Operations Manager in Indonesia, has been heavily involved with the hydrofrack program from the early concept stage to the implementation and practical fracking stages. He said, “It is excellent to see the desired results are now being delivered. The teams continue to grow their working knowledge of the systems required to safely frack and help the already professional working partnership between PTFI and Major Drilling become even stronger.”

Work in Indonesia continues and will further support six underground diamond drills coupled with three complete hydrofracking setups in the mine. These setups will continue to drill and frack holes in accordance with the designs to help the mine produce now and into the future.

See the full article, “Hydrofracking Yielding Promising Results at PTFI’s Deep MLZ Mine” on the PT Freeport Indonesia website, which we recommend to you as a Major Drilling Defining Read.

Major Drilling is one of the world’s largest drilling services companies with expertise in specialized drilling including blockcave monitoring, hydrofracking and other mine services. Contact us today to get started on your next specialized drilling project.

Frack pump and pipes set up at Freeport Indonesia’s DMLZ mine.

LM110 Drill used by Major Drilling Indonesia.

Frack pump set up at Freeport Indonesia’s Deep MLZ mine.

This underground pump system is part of Major Drilling’s hydrofracking set up in Indonesia.