Major Drilling promotes a proactive approach to the

health and safety of all our employees.

Our safety system has been developed to meet or exceed all applicable government and client standards.

By partnering with industry leaders in behavioral safety, incident investigation, workers’ compensation, and OSHAS standards, we have built a comprehensive integrated management system.

Our system utilizes the latest technology to ensure all branches have access to the most up-to-date standards and any information we gain is shared with the entire Company quickly. Our crews are well trained, dedicated employees who know safety excellence occurs when every employee understands their right and responsibility to work safely every day.

Our Safety Programs

Major Drilling’s system elements have been developed according to OHSAS 18001 standards. We track the details of each incident globally in our Intelex system by entering details of incidents regardless of severity of loss; this helps build an ongoing picture of risk that helps identify emerging trends and track the effectiveness of our efforts.

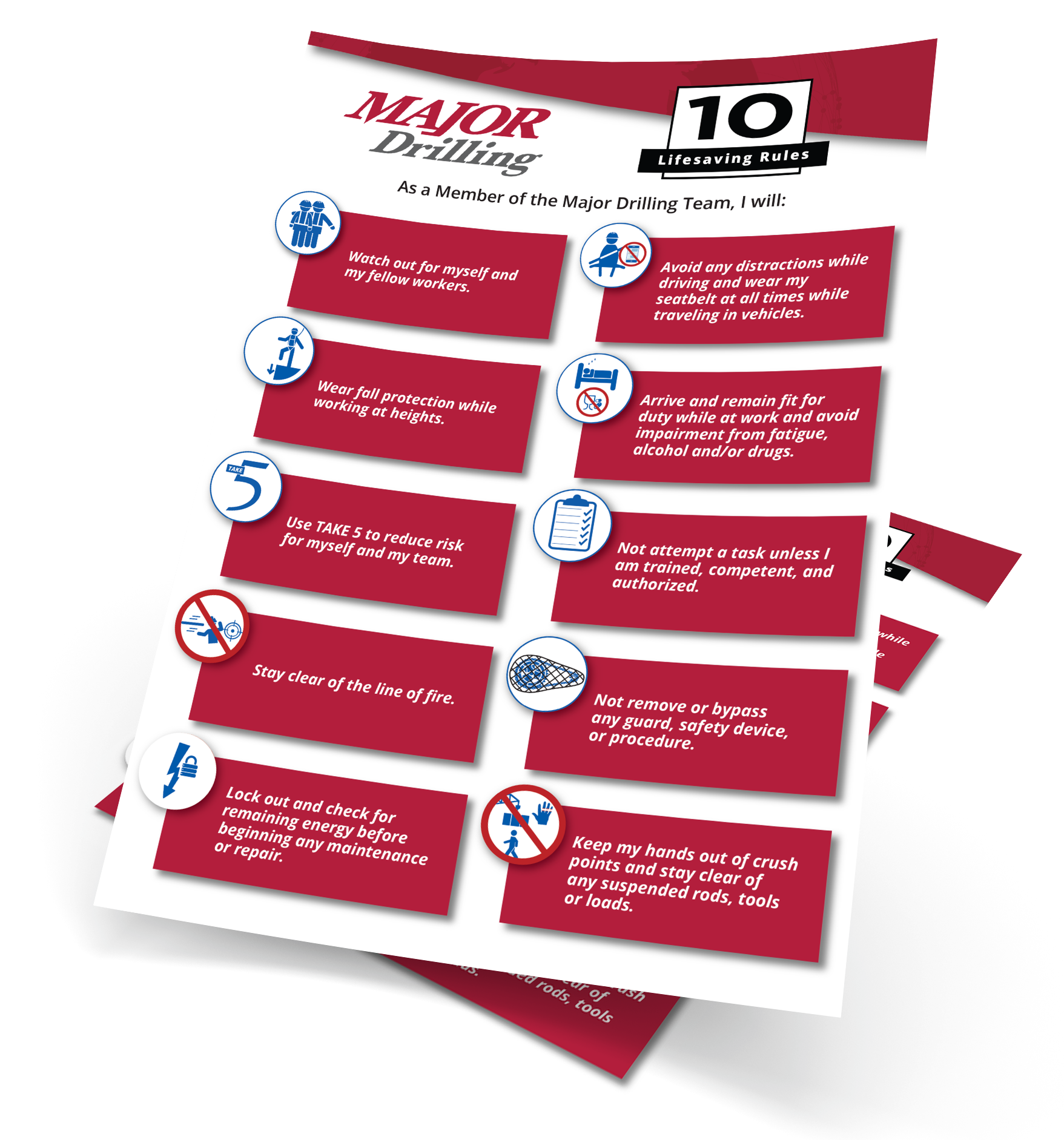

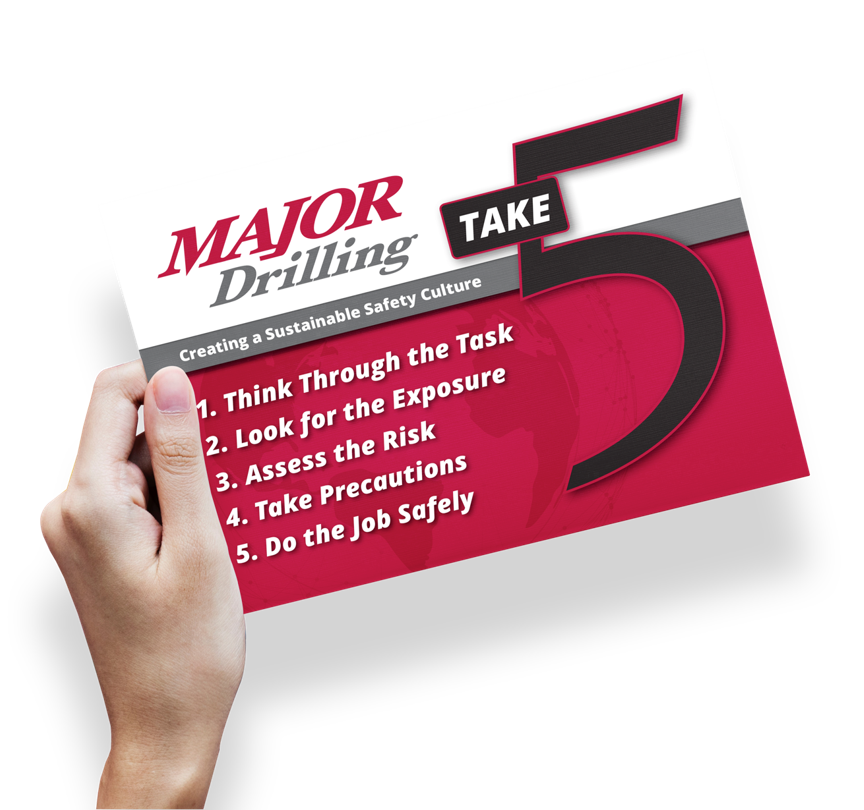

Major Drilling is committed to a comprehensive management system while not forgetting that safety begins in the field with our fundamental programs such as TAKE 5. This is the Company’s field-level simple risk assessment tool used to identify and control hazards encountered on site at the moment and in the environment where the task is being completed. We have also developed our own “10 Lifesaving Rules” to highlight serious risks and the controls which allow us to prevent serious injuries. We also have a continuous improvement plan to keep our elements, processes, procedures and management practices above industry standards.

“Safety is a core value in our operations. These 10 lifesaving rules best communicate many of Major Drilling’s key risks and controls to our team and to our customers.”

Ben GrahamVice-President of HR & Safety

10 Lifesaving Rules

To help express this value, we have introduced our 10 lifesaving rules.

-

Watch out for myself and my fellow workers.

-

Avoid any distractions while driving and wear my seatbelt at all times while traveling in vehicles.

-

Wear fall protection while working at heights.

-

Arrive and remain fit for duty while at work and avoid impairment from fatigue, alcohol and/or drugs.

-

Use TAKE 5 to reduce risk for myself and my team.

-

Not attempt a task unless I am trained, competent, and authorized.

-

Stay clear of the line of fire.

-

Not remove or bypass any guard, safety device, or procedure.

-

Lock out and check for remaining energy before beginning any maintenance or repair.

-

Keep my hands out of crush points and stay clear of any suspended rods, tools or loads.

The rules will be incorporated into the induction training, reinforced with staff on a regular basis and placed on all job sites

TAKE 5: Creating a Sustainable Safety Culture

- Think Through the Task

- Look for the Exposure

- Assess the Risk

- Take Precautions and Remove the Risk

- Do the Job Safely

Enacting Take 5 means:

- Strictly following all applicable Safe Work Procedures (SWP) and company safety standards

- Inspecting all equipment before use

- Locking out equipment prior to completing any maintenance

- Participating in internal and third-party safety audits to ensure the system continues to meet the evolving risks in our industry

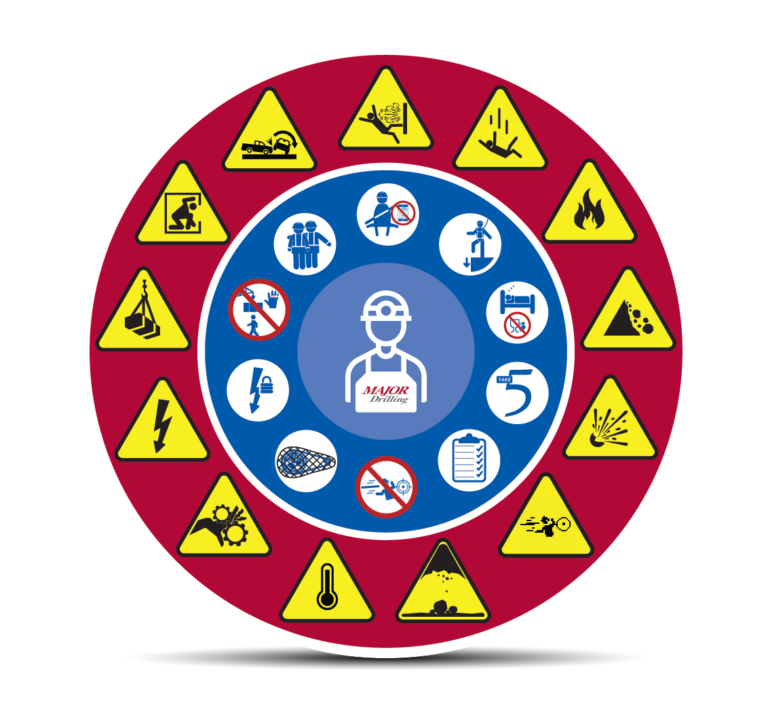

Critical Risk Management

Our newest safety initiative comes in the form of our Critical Risks Management Program. Our CRM program will serve as a key part to a critical incident prevention strategy. It will provide the controls deemed necessary to prevent potential fatalities, serious incidents and/or injuries that come from our most common hazards and risks encountered in our daily business tasks.

Every critical risk identified in this program will have a set list of critical controls. Every shift, when an employee encounters a critical risk logo they will need to stop and complete the corresponding critical control checklist.

Awards

-

Safe Day Every Day Gold Award Canada 2023

-

TOP 100 Enterprises of 2023 – Government of Mongolia and the Mongolian National Chamber of Commerce

-

Canadian Diamond Drilling Association (CDDA) UG Safety Group Achievement Award 2023

-

Best Drilling Company – Mongolia Drilling Association 2019

-

Safe Day Everyday Gold Award Canada 2018

-

Safety Performance Achievement and Recognition Indonesia 2018

-

National Drilling Association (NDA) Award 2017

-

Safe Day Everyday Gold Award Canada 2017

-

Rio Tinto Growth & Innovation Award 2017

-

Safe Day Everyday Gold Award Canada 2016

-

Cameco Global Safety First Award Canada 2015

-

Resolution Copper Contractor of the Year 2014-2015

-

Cameco Global Safety First Award Canada 2014

-

Cameco Global Safety First Award Canada 2013

-

Cameco Global Safety First Award Canada 2011

-

Supplier Award – Peabody Winsway Resources 2010

-

Cameco Global Safety First Award Mongolia 2010

-

Best Safety Contractor – Oyu Tolgoi (Rio Tinto) 2009