As part of that growth, underground reverse circulation is a new service complementing existing diamond coring, geotechnical, hydrology and directional drilling. PQ rod handling is a new feature on some drills that is helping diversify the underground fleet.

“The underground drills, some with PQ rod handling and advanced safety features, are boosting the Major Drilling fleet at the right time, with the right specs for our clients,” Nick Floersch, Major Drilling USA Underground Operations Manager, said. “We’re excited to add more of these underground drills to our operations.”

Smart 6 underground drill with rod handler

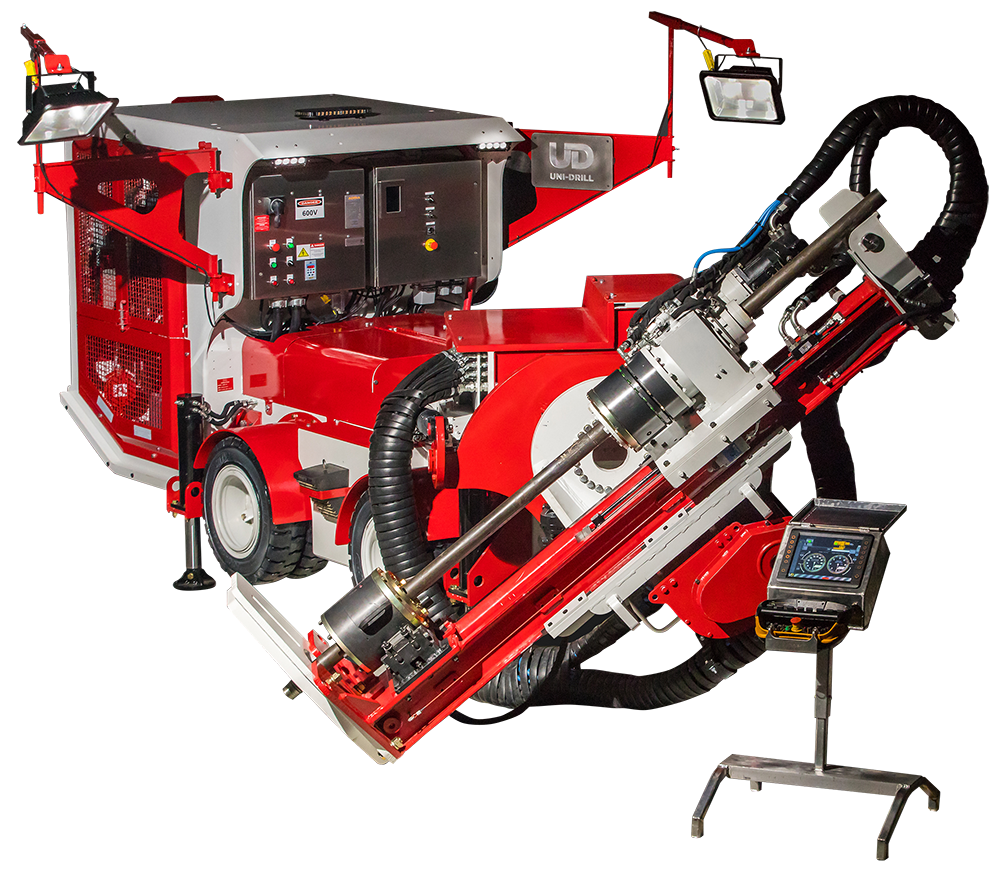

Major U600 mobile underground core rig

Smart 8 with PQ drilling capability

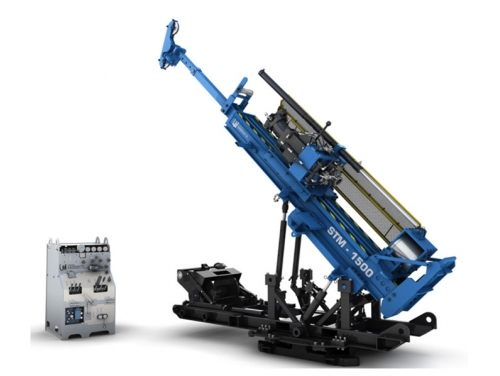

STM 1500 skid rig

LM110 with PQ drilling capability

LM90 with rod handling

Epiroc MCR Rig

Sandvik DU311TK RC Drill

Major Drilling maintains a fleet of diverse underground drills that are stationed at various locations around the world. This includes mobile carrier rigs for maximum mobility underground. Underground operations like coring, RC, production drilling, dewatering and other mine services are available at many of its worldwide branches. The acquisition of new underground drills is advancing specialized drilling areas of expertise already augmented by the 2014 acquisition of Canada and USA underground percussive longhole drilling services company Taurus Drilling.

Drills like the Smart 6 underground exploration rig are helping provide better results especially when comparing drilling job price versus cost per meter. The U600, introduced in 2019, is a mobile underground core drill with heavy duty remote control functions. Each drill comes with specific capabilities to maximize exploration and mining potential.

Newly built MDR700 in Mongolia

U600 remote controls allow for hands-free rod handling

Underground with Resolution Copper

The Smart 8 with PQ capabilities is a core drill that addresses extremely difficult processes for client Resolution Copper in Arizona, USA. The site demands extremely technical core drilling processes. The Smart 8 can go as deep as 2,000 meters with a “smart” Automated Pilot Control system (APC) combined with the automated rod handler.

Resolution relies on underground drilling to lay the foundation to become a world-class copper producer. Geotechnical characterization drilling, completed by Major Drilling crews in late 2021, received positive feedback from the project’s geologist for safe and successful completion and development of the multi-year, hands-free core tube handling system.

“We’re in a partnership with Major Drilling on the surface and underground that’s been a successful for more than 10 years,” Michael Bierwagen, Drilling Supervisor / Geologist at Resolution Copper, said. “Many unique challenges underground are overcome with equipment like the Smart 8 so our progress can someday enter the production phase.”

USA drillers examine core drilled with the Smart 8 underground core drill

Resolution is a joint venture owned by Rio Tinto (55%) and BHP (45%). Working more than 2,000 meters underground comes with unique challenges and accomplishments. The partnership has achieved zero injuries in the 2021-2022 underground drilling campaign.

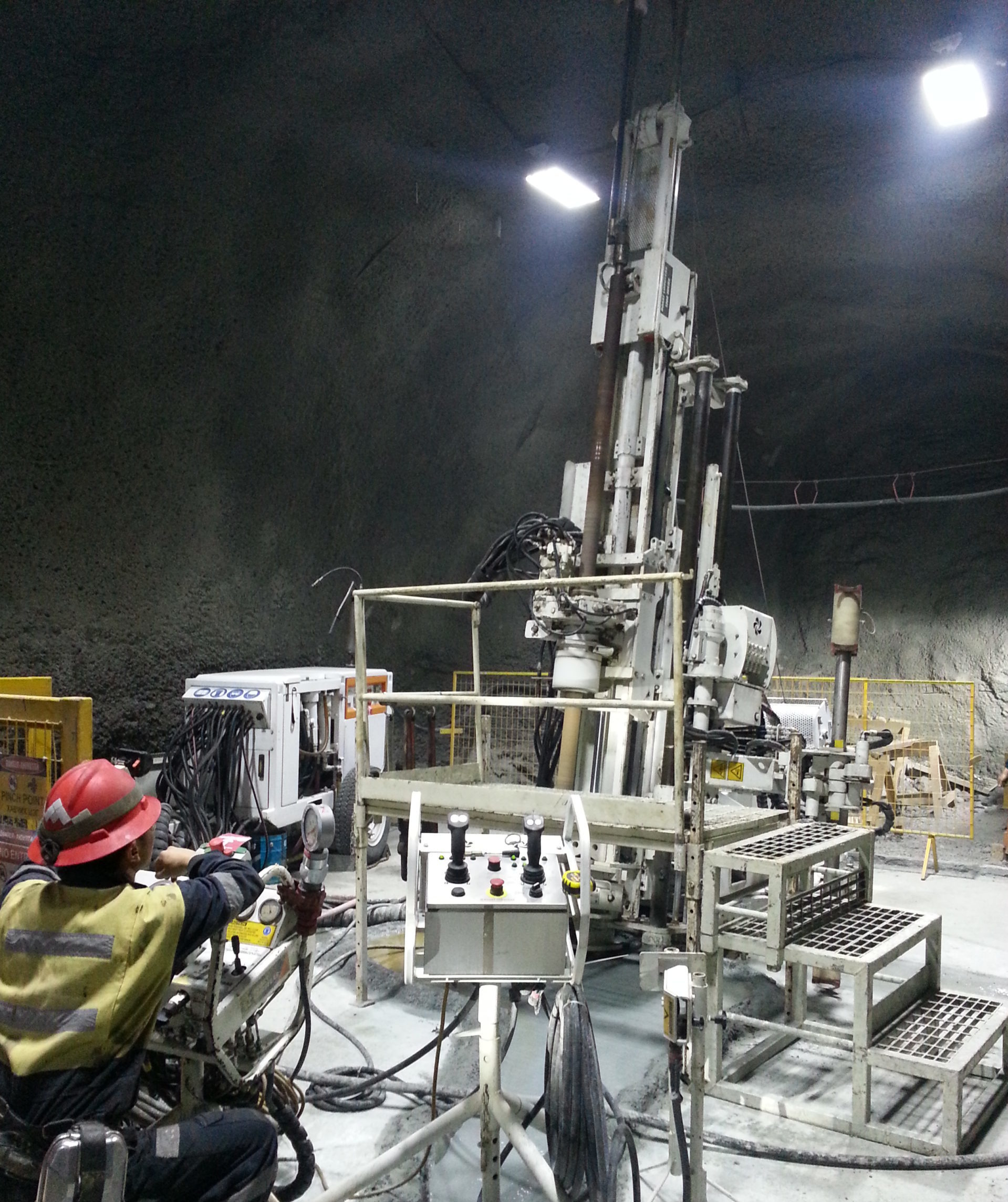

Underground in Indonesia

At the Grasberg Mine in Indonesia, Major Drilling teams used underground drills to become experts at now complete block cave pre-conditioning drilling and dewatering. Crews would drill the holes, install packers and pump high pressure water through the drill rods to fracture the ore body as part of block cave preconditioning.

“We worked closely with Freeport’s technical teams as we progressed with implementing this highly technical process for pre-conditioning block cave hydrofracking,” Kerryn Hornby, Major Drilling Indonesia General Manager, said. “We’re proud to support Freeport and develop these underground drilling skills with our Indonesia teams.”

Also in Indonesia, the Branch introduced the LM110, a new drill type never before used in the country. The underground core rig with rod handling capabilities can core up to 600 meters of PQ. Unlike other drill rigs within Indonesia, it can directly handle P-sized rods and core barrels.

“The LM110 greatly reduces hazards associated with manual handling tasks,” Jonathan Emmerzael, Indonesia Branch Operations Manager, said. “We’re pleased to bring greater diversity to our Indonesian fleet and continue our specialized drilling expertise for clients throughout the region.”

Underground in Mongolia

In 2002, Major Drilling opened operations in Mongolia. The Branch is fully equipped with maintenance facilities to dispatch drills to projects including Oyo Tolgoi, a vast developing copper mine owned by the government Mongolia and Turquoise Hill Resources (majority owned by Rio Tinto). For more than 20 years, Major Drilling Mongolia has served as a key part of the family of contractors supporting gold and copper production both from the surface and underground.

MDR700 at a Major Drilling Mongolia underground drill site

Teams have drilled boreholes for cave tracking systems, part of large-scale block cave projects. The Mongolia’s Branch’s capable maintenance crew dispatched a newly rebuilt underground MDR700 drill to Oyu Tolgoi. In 2020, the Branch received the “Best Employer of Umnugovi aimag” (South Gobi province) from the provincial governor’s office for training, job creation and diversity initiatives. The Mongolian Drilling Association awarded Major Drilling Mongolia as the “Best Drilling Company 2019” based on meters drilled, training and innovation. Drilling teams reached record depths in Mongolia including several holes over 2,000-meters deep at PQ3 diameter.

Ongoing Investment in Underground Specialized Drilling

Underground drilling is always performed using top safety programs including the Critical Risk Management program. Safety is at the heart of Major Drilling. The well-being of each employee is a top priority and part of the overall sustainability and success of the company’s position as the world leader in specialized drilling.

Contracts for underground drilling are projected to rise as exploration increases. Major Drilling continues to invest in new drills with the latest innovations and safety features to meet demand. As the delivery of underground exploration drills continues in 2022, Major Drilling will continue to lead out as the preferred specialized drilling contractor in the mining industry.

Follow Major Drilling on LinkedIn, Twitter, Facebook and Instagram to receive the latest company news and updates. Established in 1980, and publicly traded as Toronto Stock Exchange ticker symbol TSX: MDI, Major Drilling is the preferred specialized drilling contractor for all tiers in the mining industry. The company operates on five continents as the world leader in specialized drilling using mining industry ESG principles to guide sustainability. As the leading mining supplier and drilling contractor for specialized contracts, Major Drilling is a trusted mining partner through industry upturns and ongoing exploration projects. Learn more about how to make your next drilling project safe and successful with Major Drilling.